TRIMTEC TR: multipurpose profiles in different materials

TRIMTEC TR: multipurpose profiles in different materials

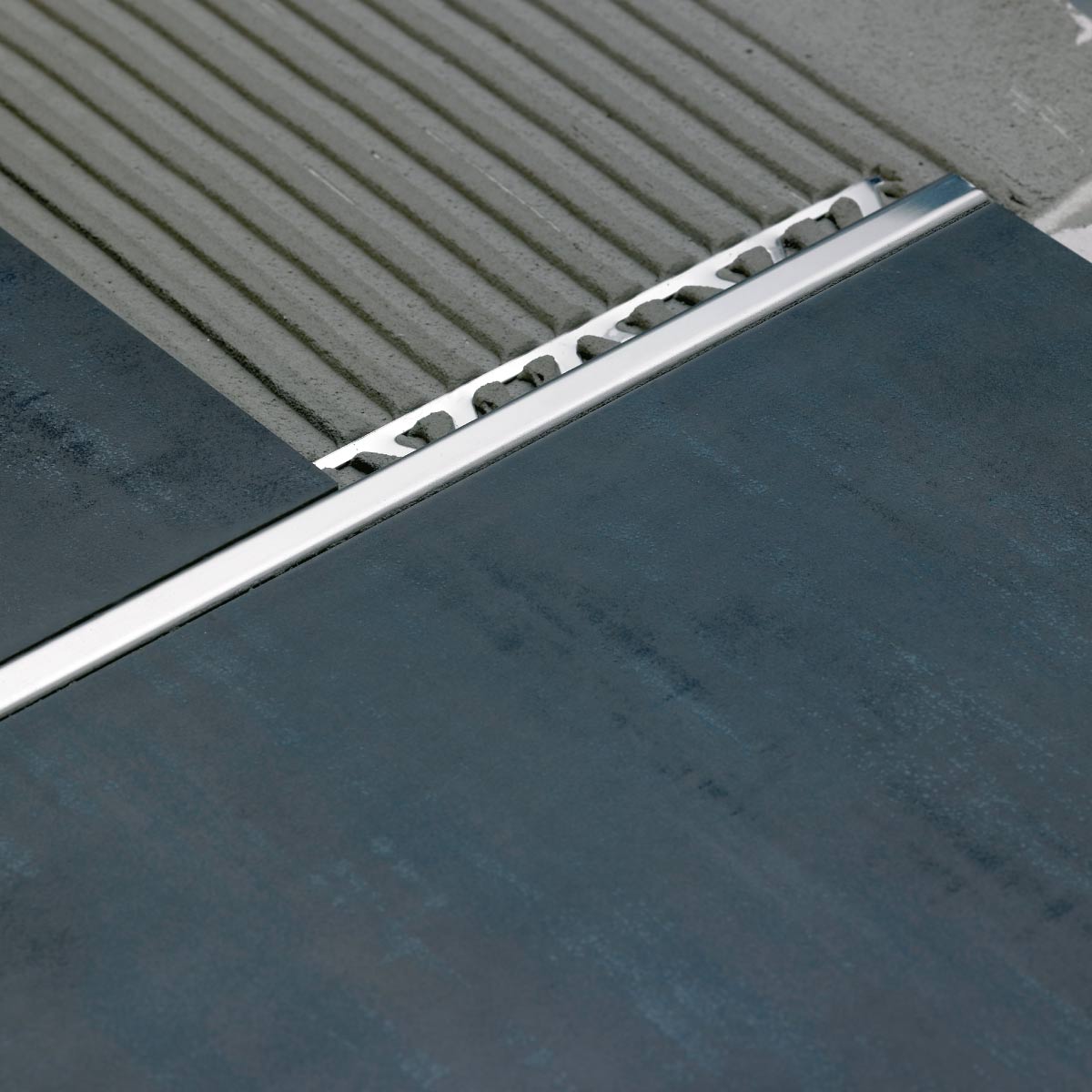

TRIMTEC TR is a complete range of brass, aluminium and stainless steel trim profiles designed for fast and efficient installation of any flooring type, regardless of size and thickness. TRIMTEC TR is available in various heights from 2 to 30 mm, matching different tile thicknesses. In the aluminium and brass versions, a dovetail groove maximizes the grout grip and edge protection for both vertical and horizontal tile laying. TRIMTEC TR profiles are conceived for tile laying, but can also be used with other types of flooring such as stone, wood and industrial resin floors. TRIMTEC TR profiles are mainly used as transition trims between two types of flooring (for example between tiling and moquetteing) and as expansion joints when two lengths are laid side by side. They can also be used as trimming for ceramic skirtings and as edge protection for any floor thickness. In some cases the profiles may be used as entrance mat framing.

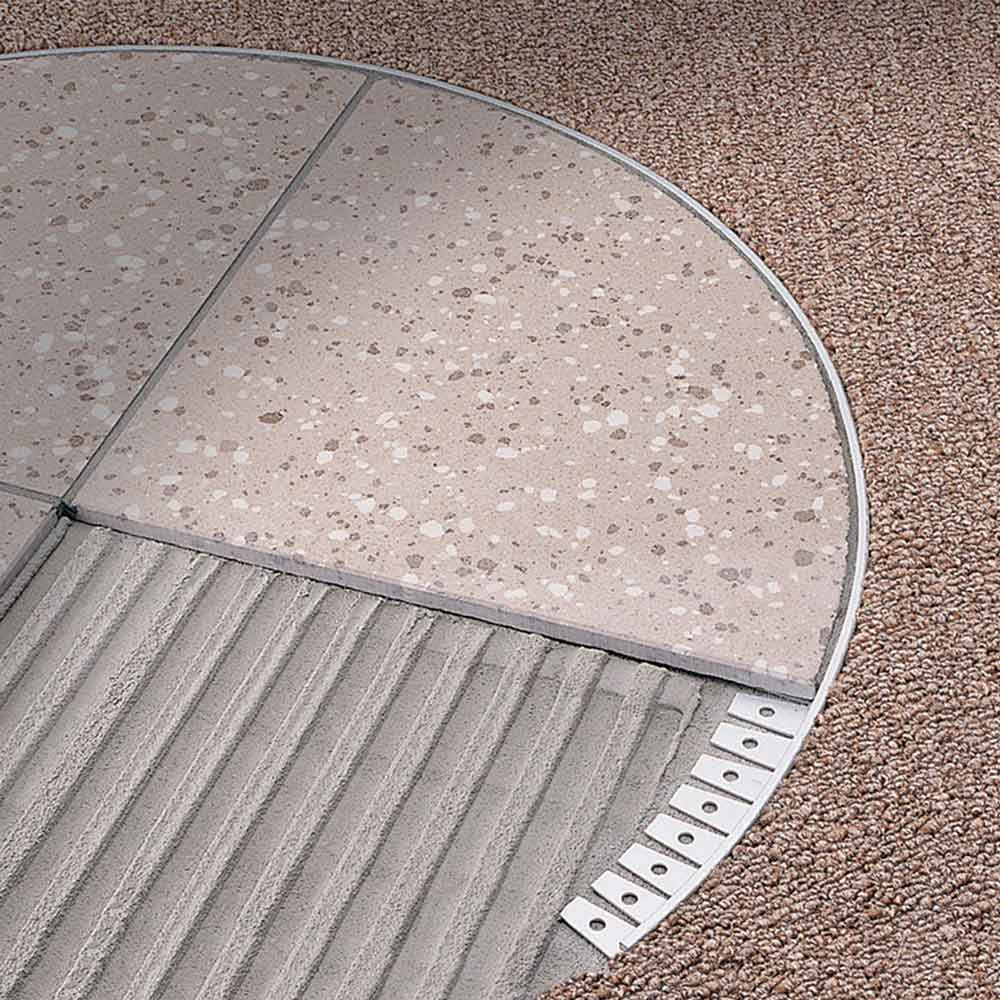

TRIMTEC TR Curveline: the bendable version of the TR

TRIMTEC TR series is also available with a specially-cut flange that allows shaping for curved edges and inlays. To order: add the letter D to the product code.

TRIMTEC TR how to install

1) Choose the trim size according to the tile thickness. The trim should be 0.5+/-1mm lower than the tile, therefore not exceeding the height of the tile. 2) Apply tile adhesive. 3) Cut the profile to required length, leaving extra space for linear expansion. The perforated flange of the trim is then firmly embedded into the adhesive and aligned. 4) Trowel an additional layer of adhesive over the perforations in the profile and in the dovetail groove of the vertical section. 5) Leave a tiny gap of approximately 0.5+/-2mm between the trim and the tile for final grouting.

-

Trimtec TR-I in Stainless Steel AISI 304 - DIN 1.4301 - Polished, Brushed or sanded

This Stainless Steel profile ensures high resistance to most diluted chemicals found in laboratories and aggressive detergents present in food processing plants, commercial kitchens, slaughter houses, breweries, public toilets and hospitals. Available in polished (IL), brushed (IS) or sanded (IX) Stainless Steel.

Stainless Steel 304 / Polished

H (mm) Art. 2 TR 20 IL 3 TR 30 IL 4,5 TR 45 IL 6 TR 60 IL 8 TR 80 IL 10 TR 100 IL 11 TR 110 IL 12,5 TR 125 IL 15 TR 150 IL 17,5 TR 175 IL 20 TR 200 IL 22,5 TR 225 IL 25 TR 250 IL 27,5 TR 275 IL 30 TR 300 IL Stainless Steel 304 / Brushed

H (mm) Art. 4,5 TR 45 IS 6 TR 60 IS 8 TR 80 IS 10 TR 100 IS 11 TR 110 IS 12,5 TR 125 IS 15 TR 150 IS 17,5 TR 175 IS 20 TR 200 IS 22,5 TR 225 IS 25 TR 250 IS 27,5 TR 275 IS 30 TR 300 IS Stainless Steel 304 / Sanded

H (mm) Art. 10 TR 100 IX 11 TR 110 IX 12,5 TR 125 IX -

Trimtec TR-I in Stainless Steel AISI 316 - DIN 1.4401 - Polished

Stainless steel profile, ensures excellent resistance to corrosion.Used mainly in the food and chemical sector: butchers, public kitchens, laboratories, hospitals and bathrooms.AISI 316 stainless steel is used in marine environments. Although it has better corrosion resistance characteristics than all other steels, before using it in particularly aggressive environments, check its suitability for use. Not to be used in environments where products or materials containing chlorine are used.Available with polished surface (IL)

Stainless Steel 316 / Polished

H (mm) Art. 6 TR 60 ILM 8 TR 80 ILM 10 TR 100 ILM 11 TR 110 ILM 12,5 TR 125 ILM 15 TR 150 ILM -

Trimtec TR-A in Aluminum - Natural or Anodized

This profile is produced in conformity with UNI standards. It has limited mechanical and chemical resistance. During installation, excess adhesive and grout should be removed immediately to avoid stains. The exposed surface may change color or darken over time.

Aluminum / Natural

H (mm) Art. 2 TR 20 AN 3 TR 30 AN 4,5 TR 45 AN 6 TR 60 AN 8 TR 80 AN 10 TR 100 AN 11 TR 110 AN 12,5 TR 125 AN 15 TR 150 AN 17,5 TR 175 AN 20 TR 200 AN 22,5 TR 225 AN Aluminum / Anodized

H (mm) Art. Color 2 TR 20 AS Silver 3 TR 30 AS Silver 4,5 TR 45 AS Silver 6 TR 60 AS Silver 8 TR 80 AS Silver 10 TR 100 AS Silver 11 TR 110 AS Silver 12,5 TR 125 AS Silver 15 TR 150 AS Silver 17,5 TR 175 AS Silver 20 TR 200 AS Silver 22,5 TR 225 AS Silver -

Trimtec TR-O in Brass - Natural or Polished

This brass profile is produced with first grade raw material, guaranteeing resistance to chemical and mechanical stress and wear. It is particularly suitable for areas with heavy, industrial traffic as well as for domestic use. Moisture and corrosive agents may oxidize the exposed surfaces. Buffing the profile with conventional polisher will bring back its shine in no time. Available in natural brass (ON): minimum quantity required for this option.

Brass / Natural

H (mm) Art. 2 TR 20 ON 3 TR 30 ON 4,5 TR 45 ON 6 TR 60 ON 8 TR 80 ON 10 TR 100 ON 12,5 TR 125 ON 15 TR 150 ON 17,5 TR 175 ON 20 TR 200 ON 22,5 TR 225 ON 25 TR 250 ON 27,5 TR 275 ON 30 TR 300 ON Brass / Polished

H (mm) Art. 2 TR 20 OL 3 TR 30 OL 4,5 TR 45 OL 6 TR 60 OL 8 TR 80 OL 10 TR 100 OL 12,5 TR 125 OL 15 TR 150 OL 17,5 TR 175 OL 20 TR 200 OL 22,5 TR 225 OL 25 TR 250 OL 27,5 TR 275 OL 30 TR 300 OL -

-

What should the height of the perimeter profile be according to the tile thickness?

-

Which material do you recommend for wall and floor installations in humid environments?

-

Which profiles are suitable for environments with saline and chlorine?

-

What length are Profilitec’s wall and floor profiles?

-

Can a brass profile, which has been just installed, corrode?

-

What’s the difference between Trimtec TR “L” profiles and Kerajolly KJ “L” profiles?

-

Which floor profiles are most suitable for indoor use?

-

Related products

Select items and add them to the quotation list

Select the product to request a quote

| Article | Material | Finishing | Color | Installazione | H (mm) | |

|---|---|---|---|---|---|---|

|

|